One week under these conditions was thought to equate to one month of normal storage for most fat based confectionery products and those containing nuts.

Accelerated shelf life testing temperature for food.

Barnett 1980 suggested an accelerated test where packaged products are alternated daily between storage temperatures of 26 7 c 80 f and 15 6 c 60 f for 6 12 weeks.

Elevated temperature or humidity are applied to eligible products to predict product shelf life over extended periods of time up to 1 year.

Accelerated condition means temperature usually 10 13 c above the normal storage temperature of the product and rh 90 because microbial growth is maximum observed cmc is the moisture content at which the product is unacceptable by using imc cmc we can find the maximum permissible moisture in the product.

Accelerated shelf life testing.

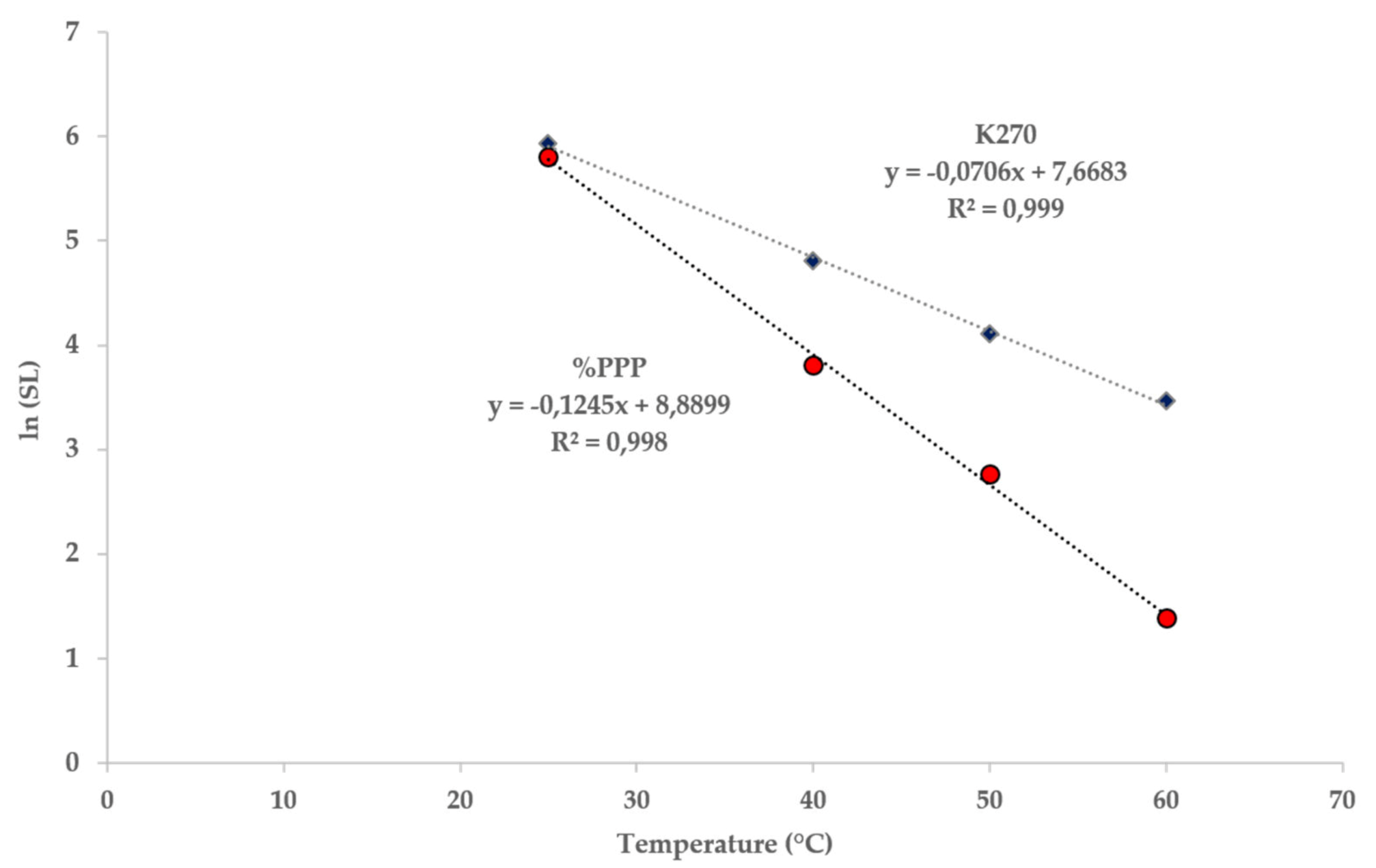

In these studies accelerated conditions i e.

Table 8 reports data relevant to the color changes of the beverage during storage at the selected temperatures.

Both methods have their place in the monitoring expected shelf life.

The q10 value of a product is the temperature quotient for a 10 c temperature difference as expressed in the equation below.

Accelerated shelf life study is performed by increasing the storage parameters time temperature humidity of the incubator conditions.